|

|

|

|

Fixing Systems for Stone Ventilated Facade

The term “ventilated façade” is used to describe the latest technology in natural stone installation. Other terms such as mechanical fixing, anchoring systems and fixing systems are also used.

Stone slabs are independently fixed to the backing wall with a cavity between the wall and the panel. This allows the replacement and repair of any slab without damaging the rest of the facade. The most important advantage of this system is not only stability but with this system, there is space between the wall and the stone causing air ventilation, which creates a natural insulation for the building. Air circulation through the cavity and open joints keeps the natural stone panels dry and clean providing natural maintenance for the long durability of the facade.

Natural stone panels are supported with stainless steel fixings at the vertical or horizontal joints; depending on the location of the slab on the facade. The fixings enable three dimensional adjustability, which provides up to 30 mm of tolerance for adjusting. This is normally adequate even if normal construction tolerances of the concrete frame are exceeded.

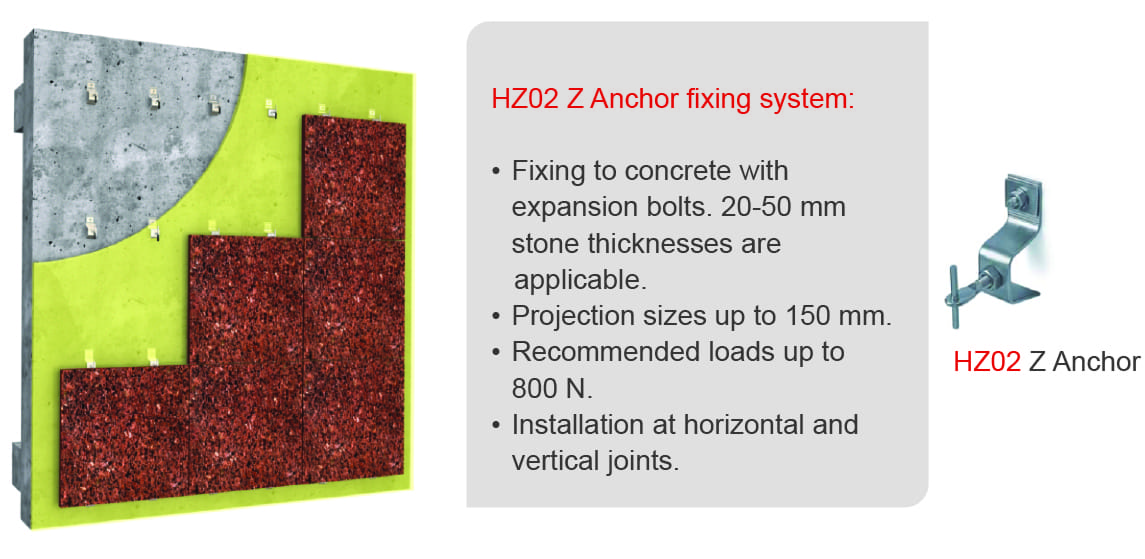

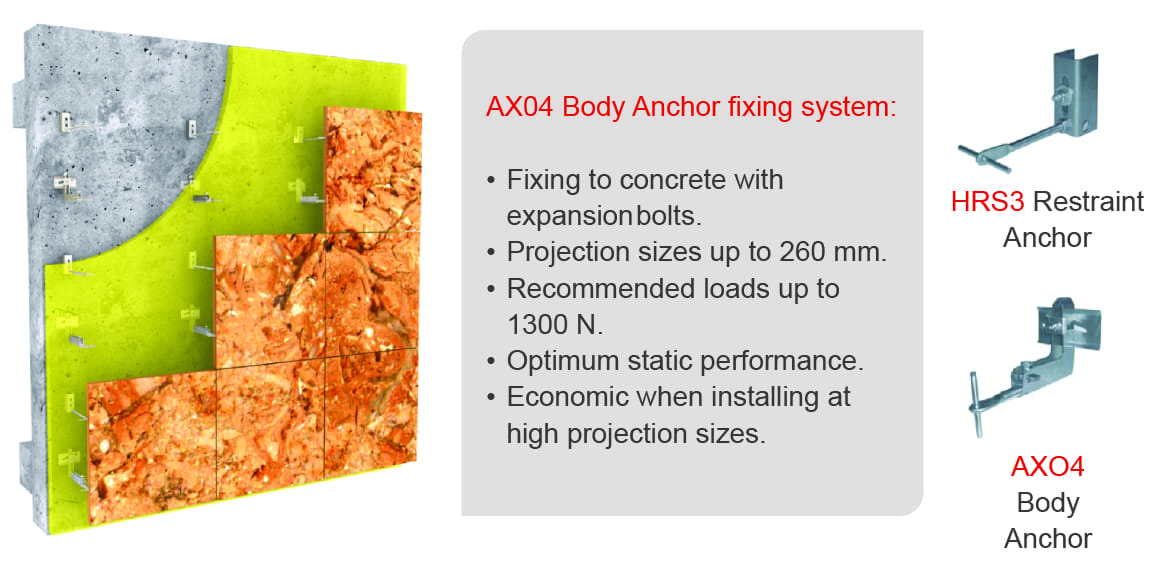

Several types of tested anchors are available, such as Z anchors, body anchors, mortar anchors and various other fixings. The main purpose of these anchors is to transfer the dead load of the panels to the building.

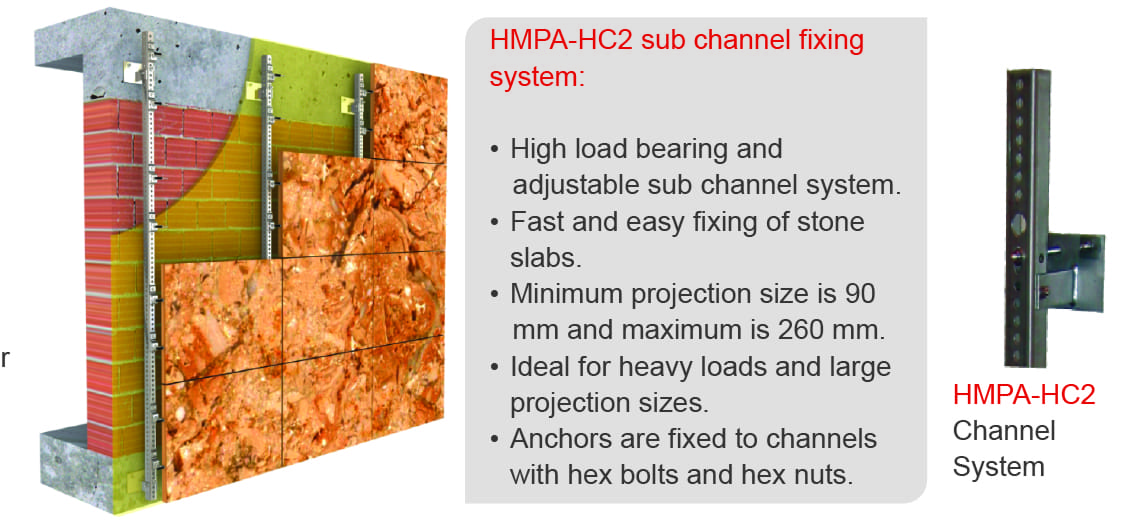

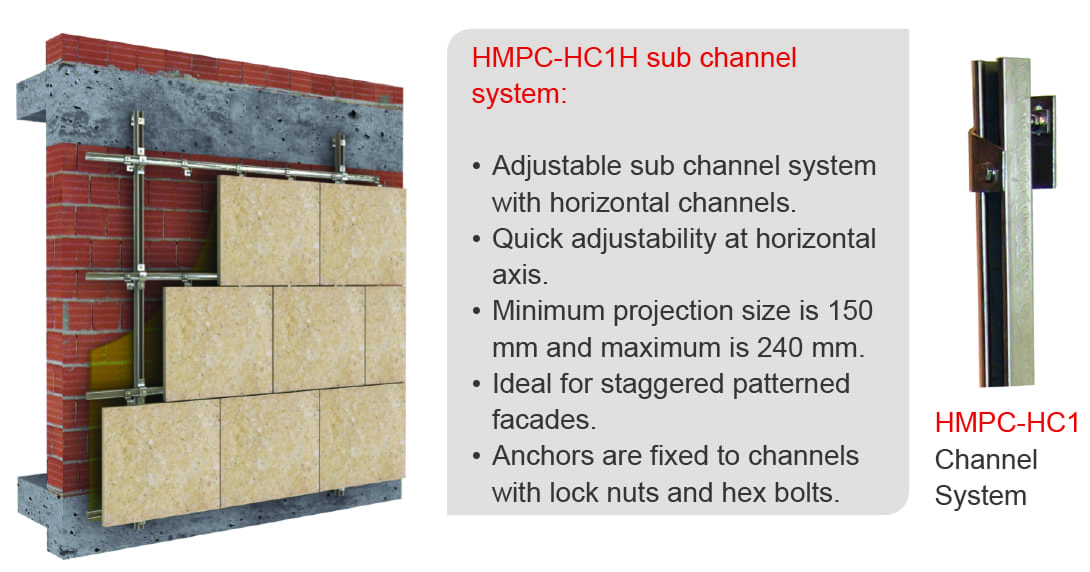

There are many types of fixing systems all used for special circumstances and the overall technical specifications of the project.

Fixing systems differ according to the dead load, size of projection, type of wall height of building, wind load, seismic load and the nature of the installation.

There is direct fixing to walls and indirect fixing to sub channel systems. Sub channels are used either when the projection sizes are too large or the walls are non-load bearing walls such as bricks or Ytong where expansion bolts cannot be used. The advantage of the system can be summarised as follows:

1. Fixings manufactured and tested to known design criteria.

2. Frame, Fixings and Bolts are all corrosion resistant Stainless Steel.

3. No bridging of cavity can occur, as brackets do no transport moisture. An open cavity is kept which allows free ventilation.

4. The waterproof barrier is at the concrete face and this continues into the window without interruption.

5. Joints between the stones can be maintained at a uniform size.

6. Thermal and substrate movement is accommodated into the joint.

7. The risk of progressive collapse is eliminated.

8. Individual stones can be replaced.

9. The fixing system greatly reduces damage to the cavity insulation and reduces cold bridging.